How we prepare for winter

Introduction

Falling snow... Subzero temperatures... Icy roads and sidewalks... Winter weather can be challenging for all Chicagoans—especially when you need to get somewhere!

To ensure our riders get from Points A to B safely and comfortably, we've developed myriad strategies to address snow, ice and subzero temperatures, all of which can impact bus and rail service.

During severe weather, our No. 1 goal is to keep service operating as close to schedule as possible for our customers, and to do so safely.

To meet that goal, our staff receives extensive training on winter-specific issues and events—training that helps us maintain the highest level of services possible when snow starts to fall and temperatures start to drop. And our equipment is thoroughly tested and prepared to ensure it’s ready for the winter season.

Our efforts

Video overview:

Rail service:

- When temperatures drop and there's risk of freezing, track switch heaters are turned on to keep them from freezing.

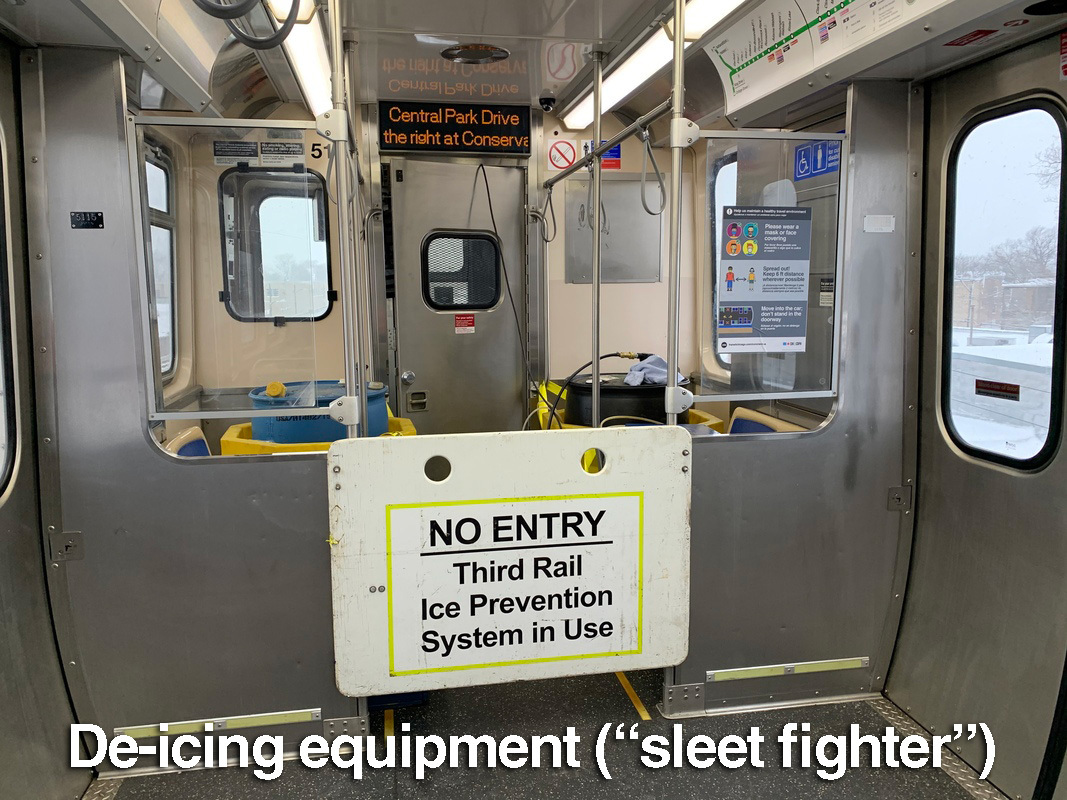

- All railcars have "sleet scrapers" that are lowered to keep the third rail clear of snow, sleet and ice. This helps to ensure trains can make proper contact with the electrified third rail to draw power and keep moving.

- Snowplow blades are attached on the front of all of our railcars so they can remove snow and ice from the track as trains move along.

- Some railcars are equipped with special equipment that distributes deicer fluid onto the third rail. This deicing fluid keeps ice from building up and getting in the way of trains collecting power.

- For lines that don't operate 24 hours, special "sleet trains" are dispatched overnight just to remove snow and ice and spread deicing fluid on the electrified third rail so the line is ready for service in the morning.

- Four diesel-powered snow fighter locomotives can reach every part of the system. These self-powered snow-fighters don't have to rely on electric power from the tracks when they're needed.

Bus service:

- All buses undergo a thorough inspection process to get ready for cold weather operation. This winter prep includes checking heaters, engine thermostats and batteries, and making sure windows, roof hatches and doors close securely.

- Buses are equipped with engine pre-heaters that circulate coolants through bus engines in cold weather so motors can be started up easily and speed the warming of bus interiors. This also reduces emissions and results in fuel cost savings.

- We work closely with local authorities, such as the Chicago Departments of Transportation and Streets and Sanitation to keep apprised of road conditions and implement reroutes if they ever become necessary.

Stations and facilities:

- Overhead heaters at all 120+ outdoor stations inspected, tested and activated before November 1, every year.

- Salt and sand get delivered to bus and rail stations and facilities.

- Track switch heaters tested and serviced to melt snow and ice, which could interfere with switch operations if allowed to build up.

- Boilers at bus garages are inspected/tested.